- Call Us+91-9966602105

- Mail Uspvschemicals@pvschemicals.in

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

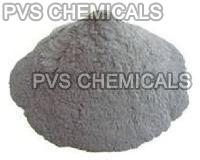

| Type | Coal |

| Shape | Lumps |

| Application | High Heating |

| Click to view more | |

Product Details

Color

Black

Purity

80%

Feature

High Combustion Rating, High Fast Flaming, High Reliability

PVS Chemicals is the most trusted PCI coal supplier in Andhra Pradesh. The products supplied by us are of the highest quality. Our team ensures that our vendors test the quality of the PCI coal before they are delivered to us. They are also very environmentally friendly.

Our products are sold at a reasonable price. We ensure that our products are delivered to our customers on a timely basis. We cater to various industries in both bulk and retail. In case you want to place your orders with us, then we are available through email and phone. So, call us now to get your quotes.

Specifications

| Total Moisture% | 9 |

| Ash% | 10 |

| Volatile Matter% | 19.0-21.0 |

| Total Sulphur% | 0.55 |

| CV (GAD) Kcal/kg | 7500 ( approx) |

| HGI | 80 |

Looking for "PCI Coal" ?

Ton

Explore More Products

Our Blogs

Raise your Query

Hi! Simply click below and type your query.

Our experts will reply you very soon.

WhatsApp Us